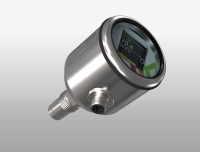

Sensors for dairies

Where turbidities and thus the appropriate changeover point in phase separation, for example, used to be determined by means of sight glasses, time-controlled processes or through conductivity measurements, companies today increasingly rely on optical measurement technology. In addition to the reduction of cleaning media, the primary objectives are the minimisation of system downtimes owing to cleaning processes, as well as the reduction of water consumption and the volume of resulting wastewater.

Read more